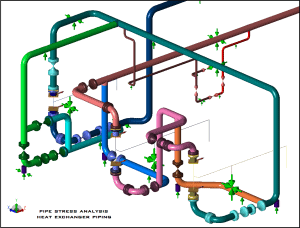

Stress analysis on piping is a critical process used to assess and predict the behavior under various conditions during their lifecycle. This analysis ensures that the piping systems can withstand internal pressures, external loads, environmental factors, and thermal expansions without failure. It plays a vital role in maintaining the safety and efficiency of industrial operations, especially in the oil and gas sector.

Types of Specialty Engineering at Align Integrity

Static Stress Analysis

Static Stress Analysis complying international codes and standards viz. ASME B31.1, B31.3, B31.4, B31.8, AS-2885, ISO14692. Analysis of critical systems like Column re-boiler, Air Fin Coolers, Pumps, Turbine, Compressors, Heaters, Jacked Piping etc.

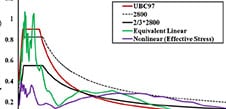

Dynamic Stress Analysis

Transient Analysis vs Modal Analysis, Time History, Response Spectrum, Harmonic Analysis. Solution to Surge (Water hammer), Slug (two phase flow) , Seismic force, Relief Valve discharge to solve various site trouble shooting problems or future problems. The analysis simulates and speculates the pipe behavior and helps mitigating the vibration problems.

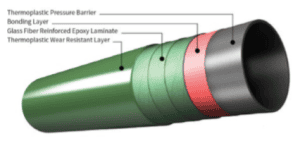

GRE Pipe Stress Analysis

Use of GRE / FRP pipe is increasing rapidly for most of the existing and new pipelines with corrosive services, acidic service. GRE / FRP pipe behavior is not similar to metallic pipe and hence experienced engineer is required to analyze GRE pipes. We perform GRE Pipe thickness calculations, analysis as per ISO 14692, UKOOA. Checking of analysis performed by vendor etc. Also support of GRE pipe to be designed using FEA. We provide complete GRE/ FRP pipe engineering

Flow Induced Vibrations

One of the most ignored aspect in pipe stress analysis during FEED or detailed engineering. Flow Induced Vibration problems are observed in High velocity, High pressure discharge systems. We perform generic calculations as well as Dynamic analysis as per Energy Institute Guidelines. We also provide solutions like Rubber isolators, dampers, springs to isolate or mitigate vibrations. In case of critical analysis Computational Fluid Dynamics (CFD) approach is adapted.

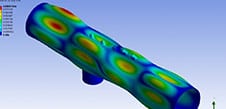

Composite Analysis

A Pipe and Structure together analysis to get actual stiffness and response to the static and dynamic loads. Composite analysis is more realistic in evaluating vibration problems near to rotating equipment like turbine, compressors, pumps.

Off-shore / FPSO Pipe Stress Analysis

Stress Analysis of Piping running on off-shore platforms, bridges & FPSO piping where various permuations and combinations of two different structure is required to be analyzed. Also analysis of Blast loads, vortex shedding, wind, wave, fatigue analysis etc. needs to be carefully analyzed.

Bending strain assessments in pipelines

Bending strain assessments are critical for ensuring the structural integrity and operational safety of these essential infrastructures. Pipelines, often subjected to various external loads such as soil pressure, temperature changes, and internal fluid pressure, can experience bending strains that may lead to deformation, cracking, or even ruptures. Engineers conduct bending strain assessments using analytical methods, finite element modeling, and field measurements to evaluate the pipeline’s response to bending forces. By understanding the strain distributions along the pipeline, they can identify potential weak points, implement reinforcement strategies, and develop maintenance protocols to prevent failures, ultimately safeguarding against environmental hazards or “Geohazards” and Geohazard impact of economic losses.

Choosing a trusted partner for that understands the these types of stress analysis, such as Align Integrity, ensures that both quality and cost are thoroughly considered through the lifecycle of a project. Whether utilizing Align Integrity on the front end for fractional engineering support to perform these specialties, or during a critical concern of your process piping, Align Integrity offers High Value Specialty Engineering for a fraction of the cost. Align specializes in providing comprehensive stress analysis services tailored to the oil and gas industry. Their expertise allows for accurate assessments, helping clients avoid costly downtime while maintaining compliance with all safety standards. Furthermore, their commitment to quality assurance ensures reliable results, building confidence in the integrity of the piping systems.

Stress analysis on piping is a fundamental practice in the oil and gas industry, safeguarding infrastructure and ensuring operational efficiency. Partnering with experienced professionals such as Align Integrity can significantly impact the reliability and safety of industrial applications, making it a wise investment.

Contact us today to partner. Efrain.Garcia@AlignIntegrity.com